justinemoody

An Ultra High Purity Gas Delivery System is an essential component in sectors where accuracy and contamination-free processes are necessary. These systems make sure the secure and effective transportation of gases with the highest possible pureness levels, playing a substantial function in semiconductor production, pharmaceutical manufacturing, and lab. Any pollutant in gas flow can result in faulty items and endangered outcomes, making the appropriate design and implementation of these systems important for preserving high quality and efficiency.

Creating an Ultra High Purity Gas Delivery System in Industry

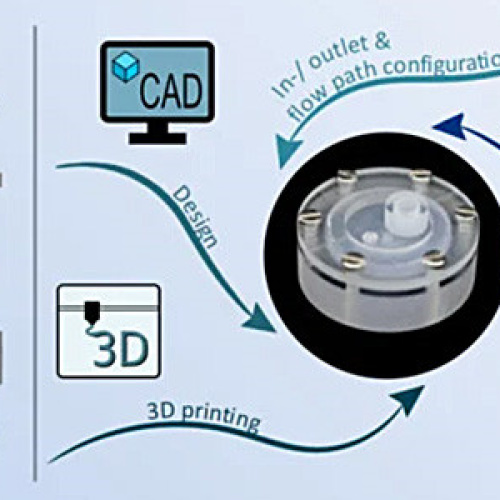

The design of an Ultra High Purity Gas Delivery System calls for mindful preparation and progressed design strategies to make sure the pureness of gases continues to be intact. The system has to consist of top quality materials such as electro-polished stainless steel and specialized filtering units to stop contamination. Leak-proof links, automated monitoring, and accurate pressure control devices are likewise crucial for maintaining regular gas quality. These systems are commonly utilized in microelectronics, aerospace, and biotechnology markets, where also the slightest contamination can affect total efficiency and dependability.

Production Ultra High Pureness (UHP) Gas and Chemical Delivery Solutions

The process of Production Ultra High Purity (UHP) Gas and Chemical Distribution Equipment involves stringent adherence to sector standards and using cutting-edge innovation. UHP gas distribution systems should be created to transfer specialty gases and chemicals without introducing impurities. This requires using advanced welding methods, gas filtration systems, and real-time tracking solutions. Industries such as semiconductor fabrication and optical fiber production rely on these systems to keep the highest degree of purity and precision throughout their production procedures.

The Significance of Ultra High Purity Regulators and Diaphragm Valves

Secret parts of any kind of ultra high pureness gas system include Ultra High Purity Regulatory Authorities and Ultra High Purity Diaphragm Valves, both of which ensure precise gas flow control and contamination prevention. These regulators are developed to preserve stable pressure degrees while protecting against fragment accumulation, while diaphragm valves supply precision flow control with minimal interior dead space. Made from state-of-the-art, corrosion-resistant products, these components play a crucial function in markets calling for outright pureness and integrity in gas distribution.

High Pureness Regulators for Specialized, Flammable, and Industrial Gas Streams

Industries taking care of specialty, combustible, and commercial gases require High Purity Regulators for Use with Specialty, Flammable, and Industrial Gas Moves to ensure security and performance. These regulators are specifically made to take care of different gas kinds while preserving pureness and avoiding leaks. Whether made use of in chemical handling, pharmaceutical applications, or semiconductor manufacturing, high-purity regulators assist maintain operational stability and secure delicate devices from contamination-related failures.

Conclusion

An Ultra High Purity Gas Delivery System is necessary for sectors that count on contamination-free gas transport. From system layout to the assimilation of high-purity regulators and diaphragm shutoffs, these systems provide dependability, accuracy, and safety and security popular commercial environments. As modern technology breakthroughs, the demand for ultra high purity gas systems will continue to grow, sustaining the advancement of sophisticated industries and making sure exceptional item top quality.